For the first time in the world, Vinmec has successfully performed a simultaneous replacement of both the pelvis and a part of the femur in a single surgery to treat an extremely rare type of bone cancer. Notably, the surgery used a new 3D-printed artificial bone design created by a team of Vietnamese doctors and engineers, tested through nearly 100 simulated scenarios to achieve the highest optimization, helping to save the patient's life and significantly accelerate recovery time compared to before.

Rare bone cancer case – Difficult solution

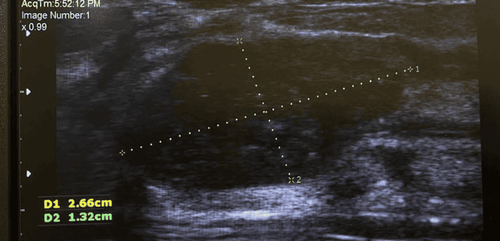

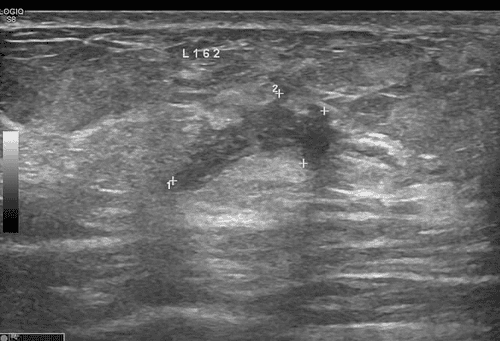

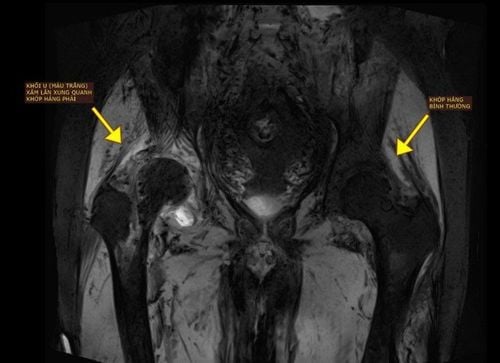

Although Vinmec performs over 100 routine bone cancer surgeries each year, the rare case of Mr. Lê Đình Thuận (63 years old) still posed a challenge for doctors at the Vinmec Orthopedic Trauma & Sports Medicine Center. Normally, bone cancer is extremely rare in the pelvis. However, Mr. Thuận's metastatic bone cancer had invaded the entire structure around the hip joint, including the pelvis, joint capsule, and upper femur.

Due to the complexity of the condition, many hospitals do not have optimal solutions for bone cancer, with most opting for surgery to remove one side of the pelvis to save the patient's life. Seeing the unfavorable outcomes of this approach, such as disability, being bedridden, severe psychological impact, and low post-surgery survival rates, the patient and family have repeatedly refused treatment.

When receiving the bone cancer case, the doctors at Vinmec Orthopedic Trauma Center once again determined that the key is that after radical surgery to remove the malignant tissue, the pelvic and femoral defects must be reconstructed to allow the patient to move and walk. With high expertise and extensive experience in bone cancer treatment, combined with Vinmec's "specialty" of painless surgery and the use of advanced technologies such as 3D and robotics, organizing and performing such a large and complex surgery did not deter the team. However, the most challenging problem here was choosing the type of material and method for grafting artificial bones to restore the shape and function of the bone in the body's most weight-bearing area after removal.

There have been some cases of 3D-printed titanium pelvic replacements reported worldwide. However, to date, there has been no recorded case of simultaneous pelvic and upper femur replacement for cancer treatment. Other bone reconstruction solutions, such as using screws and PEEK bone grafts, cannot create a biological connection with the pelvis or are not strong enough to withstand body weight, and it is difficult to restore muscle-tendon attachment points. Therefore, after bone cancer surgery, the ability to sit, stand, or walk is extremely limited.

"There is no reference from the world. Both domestically and internationally, no equipment manufacturer has a ready-made artificial pelvic solution for this case. Ordering foreign research and manufacturing would take at least 2 months, while the patient needs surgery as soon as possible to prevent tumor progression. Moreover, the long manufacturing time abroad and the lack of direct involvement of the operating doctor would make surgery extremely difficult and limit the solutions for handling complications during surgery. The only way to perform accurate and safe surgery is for the surgical team to design the artificial bone implant for this patient," shared Prof. Dr. Trần Trung Dũng, Director of Vinmec Orthopedic Trauma Center.

Racing against time to research and create artificial bones

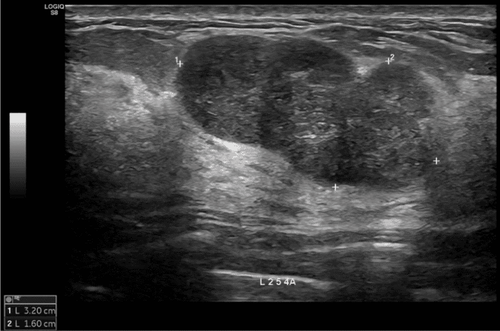

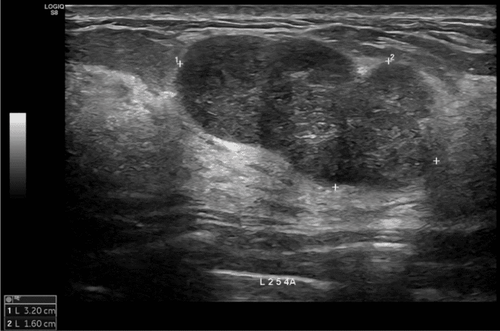

After more than 2 weeks of racing against time, continuously testing nearly 100 different shape and structure samples with simulated scenarios of daily body load, the surgical team and engineers selected the optimal design for the case. Dr. Phạm Trung Hiếu, Deputy Director of the 3D Technology Center in Medicine, at VinUni University, said: "We used a honeycomb-like structure to simulate the pelvic bone, making the entire artificial bone lightweight, weighing less than half of the real bone. The contact surface with the healthy bone is rough with micro-pores to stimulate bone cells to grow on the artificial bone surface over time, enhancing post-surgery stability. Made from biocompatible medical titanium alloy, after 3D printing and heat treatment, it can withstand more than 10 times the load of real bone while ensuring elasticity and durability comparable to the bone tissue of a young adult. In this design, instead of using multiple screws or plates to fix to the remaining pelvic wing, which could risk bone resorption or make the design bulky and difficult to fix accurately, the engineers used only one large-diameter intramedullary screw inserted straight into the bone axis along with two external locking screws, making the entire bone graft structure compact and closest in shape to the real bone.

Additionally, this artificial pelvic bone is calculated to create fixed positions, helping doctors restore all attachment points of the 14 muscle tendons around the pelvic-hip joint." The sample structure was certified for mechanical properties by the Institute of Materials Science and Engineering, Polytechnic University, and the Industrial Testing and Certification Center, Institute of Energy and Mining Mechanics. After certification, the pelvic bone design was sent to Germany for production using a 3D printing system according to European CE medical implant standards. For the femur, the surgical team used a modular titanium artificial femur that has been routinely deployed at Vinmec for the past 3 years. The production and import of this foreign sample product took only 1 week, much less than the minimum 2 months if ordered from start to finish. Therefore, the bone cancer surgery was promptly carried out at the end of December 2023 as planned, just nearly 1 month after the patient was admitted.

Miraculous Recovery: Sitting up in 2 days, walking in 10 days

With a carefully and comprehensively prepared surgical plan and the support of multidisciplinary teams including vascular surgery, digestive surgery, urology, and interventional radiology, the surgery involving two locations was completed in 8 hours without any complications. Typically, bone cancer surgeries that only replace the pelvic bone can take 8-12 hours. Throughout the surgery, with the assistance of a personalized 3D surgical navigation system, the bone cuts containing the tumor were removed with 99% accuracy compared to the plan. Additionally, with the optimal design, the artificial bones of both the pelvis and femur were perfectly fitted and precisely connected to the patient's healthy bone. All muscle tendon and nerve blood vessels removed from the bone tumor were safely reattached to the titanium artificial bone. With selective embolization of the tumor-feeding branches performed right before surgery, the amount of blood loss during surgery was much less than expected, and the patient only required 3 units of packed red blood cells, compared to the 2-6 liters of blood loss typically seen in other pelvic bone cancer surgeries. On the second postoperative day, Mr. Thuận was able to sit up firmly on his own, and after 10 days, he could proficiently move with crutches for up to 50 meters without any difficulty or pain. The recovery time in this case, compared to some domestic and international reports on artificial pelvic bone replacement, was reduced to only one-third of the time.

"When I saw the computer simulation before surgery, my hope of walking was just a spark. Now I can walk, and I truly believe that Vinmec doctors can achieve very difficult things that very few hospitals in Vietnam can do," Mr. Thuận expressed his sincere admiration upon discharge.

The success of this "2-in-1" surgery - one of the most complex bone cancer surgeries ever performed at Vinmec Orthopedic Trauma Center - has affirmed the expertise and precise treatment strategy of the medical team. Particularly noteworthy is the creativity and efforts of all doctors and engineers to promptly create the optimal artificial bone product for bone cancer patients. It is known that the experts involved in this process have many years of experience and have been trained at leading 3D technology centers worldwide in Germany, Belgium, and Israel.

Currently, the personalized 3D surgical navigation devices researched by Vinmec and VinUni have been licensed by the Ministry of Health for circulation. With the cooperation of experts from the aforementioned 3D printing powerhouses, doctors and engineers are continuing to research and perfect artificial bone graft products from materials such as Titanium and Peek. In this context, the success of this special surgery has created a solid foundation for the 3D-printed bone graft project "made by Vinmec & VinUni" designed specifically for Vietnamese patients, with equivalent quality, suitable costs, and shorter production times compared to international standards. This project is expected to be soon approved, licensed, and widely produced to meet the needs of medical facilities nationwide.